The collision repair industry has embraced digital technology, revolutionizing how facilities operate and enhancing customer satisfaction. Digital inspections using 3D imaging and specialized software offer faster, more precise damage assessments compared to traditional methods. This shift has also improved services like paintless dent repair and car restoration, allowing professionals to execute intricate repairs with enhanced precision and efficiency. As a result, customers experience quicker turnaround times, cost savings, and superior outcomes, positioning modern collision repair facilities as tech-driven leaders in the industry.

In today’s digital era, collision repair facilities are embracing advanced technology, with digital inspections becoming a common practice. This shift transforms traditional processes, enhancing efficiency and precision. The rise of digital tools allows for detailed, accurate assessments, streamlining repairs and reducing errors.

This article explores the benefits of digital inspections, delving into how they optimize collision repair facility operations, improve customer satisfaction, and ensure superior craftsmanship.

- The Rise of Digital Technology in Collision Repair

- Benefits of Digital Inspections for Efficient Repairs

- Implementing and Optimizing Digital Inspection Processes

The Rise of Digital Technology in Collision Repair

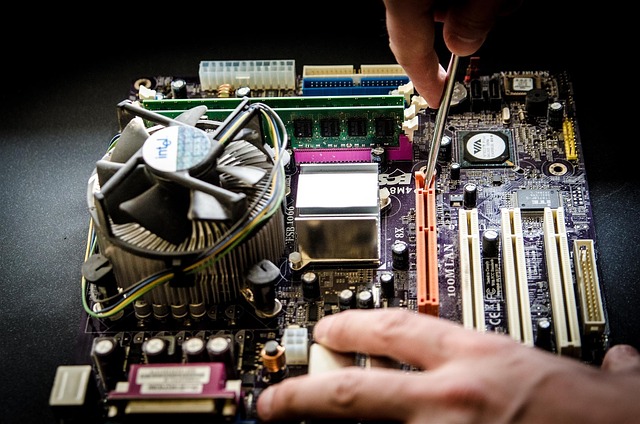

In recent years, the collision repair industry has undergone a significant transformation with the advent and rapid integration of digital technology in collision repair facilities. Modern automotive collision repair centers are increasingly adopting advanced tools and software to streamline operations, improve precision, and enhance customer experience. Digital inspections, for instance, have become a common practice, offering a more efficient and accurate assessment of vehicle damage compared to traditional methods. By utilizing high-resolution cameras, 3D imaging, and specialized software, technicians can now capture detailed images and measurements, enabling them to diagnose complex repairs swiftly.

This shift towards digital innovation is not only revolutionizing the way collision repair facilities operate but also impacting services offered, such as paintless dent repair and car restoration. With digital tools, professionals can perform intricate repairs with precision, minimizing the need for extensive repainting or full restorations. As a result, customers benefit from faster turnaround times, reduced costs, and higher-quality outcomes, solidifying the modern collision repair facility’s position as a tech-savvy, forward-thinking industry leader.

Benefits of Digital Inspections for Efficient Repairs

Digital inspections have transformed the way collision repair facilities operate, bringing numerous benefits to the table. By leveraging advanced technologies like 3D imaging and specialized software, these modern repair centers can now conduct thorough and precise assessments of damaged vehicles with remarkable speed. This real-time data not only enhances accuracy but also facilitates more efficient workflow planning.

With digital inspections, collision repair professionals gain a deeper understanding of the extent of damage, including intricate details such as vehicle dent repair needs or structural discrepancies. This level of clarity enables them to make informed decisions, choose the right repair techniques, and manage resources more effectively. As a result, customers benefit from faster turnaround times, reduced costs, and superior overall quality in vehicle collision repair services at these cutting-edge collision centers.

Implementing and Optimizing Digital Inspection Processes

In today’s digital era, collision repair facilities are increasingly adopting advanced technologies for their inspection processes. Implementing digital inspections offers numerous advantages, such as enhanced accuracy, improved efficiency, and streamlined workflows. By utilizing specialized software and hardware, technicians can meticulously document vehicle damage, creating detailed reports that facilitate precise repairs. This transition from traditional methods not only saves time but also reduces the potential for human error, ensuring higher-quality vehicle restoration across the board.

Optimizing digital inspection processes involves tailoring technology to the specific needs of a collision repair shop. This includes integrating hardware like high-resolution cameras and 3D scanners that capture comprehensive data of damaged areas. Additionally, implementing cloud-based systems allows for real-time access to inspection findings, enabling efficient collaboration among team members and seamless communication with clients. As these processes are refined, the overall effectiveness of collision repair services is significantly boosted, positioning the facility as an industry leader in both service quality and technological innovation within vehicle restoration.

Modern collision repair facilities are embracing digital technology, particularly digital inspections, to streamline their processes and enhance efficiency. By utilizing advanced tools and software, these facilities can accurately assess damage, improve communication with customers, and reduce overall repair times. Implementing digital inspection practices benefits both the business and its clients, ensuring top-quality repairs in a timely manner. This shift towards digitalization is revolutionizing the collision repair industry, setting new standards for excellence in modern auto body shops.